-

-

[2014/12/19]Basic knowledge of mobile phone connector

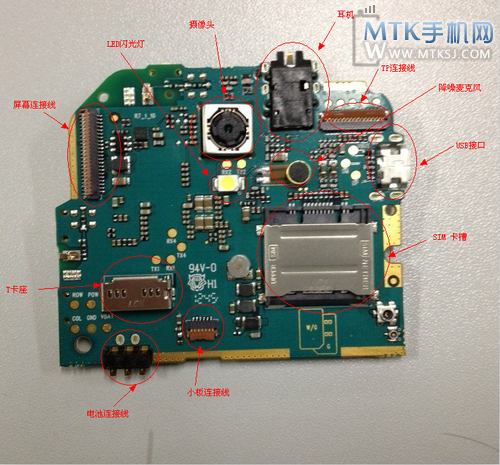

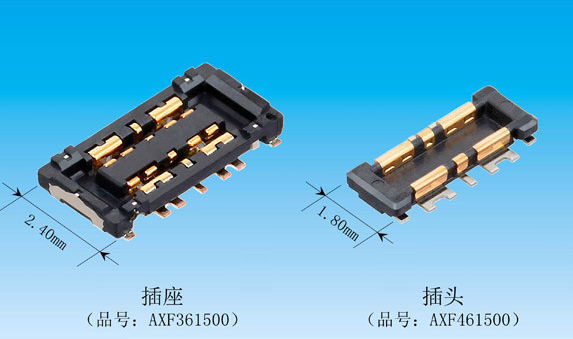

Mobile phone connector development today, can really use the mobile phone industry only five: FPC connector, board to board connector, I/O card connector, connector and battery connector, then we will be the fifth one by one analysis of mobile phone connector. Battery connector, battery connector can be divided into spring type and switch type. The technical trend of battery connector is mainly for the miniaturization, the new battery interface, low contact resistance and high connection reliability.

-

-

[2014/12/19]Structure of electric connector

The electric connector is a common type of connector, electrical connection and signal transmission between the device and the device, component and component, system and system, constitute a complete system of basic element.

-

-

[2014/11/06]Connector the newest favorite —— high current connector

Panasonic automotive electronic and electromechanical systems company achieved a "substrate of FPC with high current connectors" products, the products not only for the industry's thin, but also has large current carrying capacity, the connection part is mainly suitable for battery built-in intelligent mobile phone, tablet computer, wearable device of mobile devices such as cell.

-

-

[2014/11/06]Development of connector manufacturers and market

Connector industry is a mature industry, with even the machine technology improves connector market is also expanding. In recent years, connector manufacturers continue to increase, the market scale has reached 45300000000 US dollars, the application field of connectors are used in automobiles, computers, telecommunications, industrial, consumer electronics, aerospace, fortune field.

-

-

[2014/11/06]The great age of the new trend of the development of three major connector intelligent industry under the industrial connector

Industrial interconnection to solve an interesting trend in the field of laser direct forming scheme is (Laser Direct Structuring, LDS) technology, the realization of molded interconnect devices (Molded Interconnect Device), allows the PCB integrated as a component and connector. With this technique, the LDS compound industry has developed the use of different low temperature and high temperature plastic, this compound can be molded into the required structure, and then the laser beam exposure in all three dimensional directions. Structure created can be provided for electrical 3D shape component complex connections, while eliminating one or more PCB plate.